Study finds generator engines as key cause of methane emissions on LNG carriers

The results of a first-of-its-kind study to quantify greenhouse gas (GHG) emissions from liquefied natural gas (LNG) carriers were released on Tuesday, providing actionable data for the LNG shipping industry on methane emissions.

Methane is the second most prevalent greenhouse gas, contributing to a quarter of today’s manmade warming.

To date, there have been no direct measurements of total methane and CO2 emissions from LNG shipping. While some studies have conducted measurements of methane emissions from marine engine slip, none have published measurements of total methane emissions, which include fugitives and venting emissions from the onboard LNG and vapor handling plant.

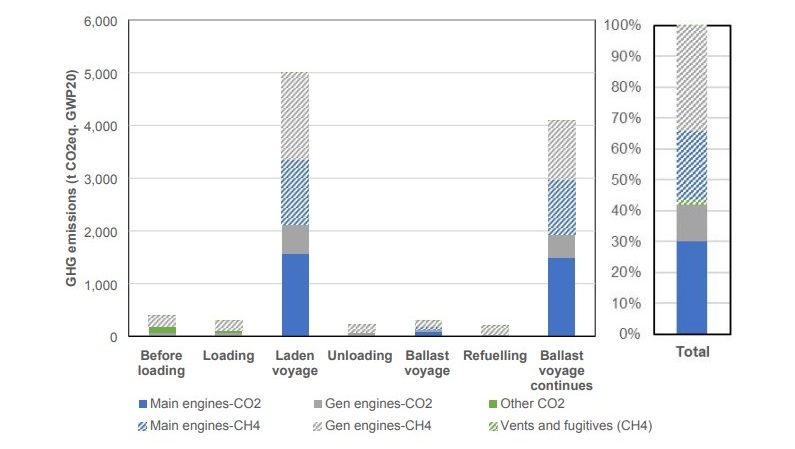

The study, led by Queen Mary University of London (QMUL), provided the first measurement and modeling of total methane and CO2 emissions from an LNG carrier on a round trip voyage from the US to Belgium and back including loading, laden voyage, unloading, and ballast voyage, measuring emissions from exhaust stacks, vents, and fugitives.

It found that venting and fugitive emissions were extremely low, contributing less than 0.1% of total greenhouse gas emissions. CO2 emissions from fuel usage were also lower than previous estimates due to improved efficiencies in modern engines and ship design.

However, according to the research, methane slip through the engines was higher than those in prior studies, averaging 3.8% across all engines: equating to 0.1% of delivered LNG. Generator engines are not typically included in emissions analyses but were the key cause of methane emissions, the study noted.

The GasLog Galveston LNG carrier (LNGC) was chosen for measurement due to the WinGD XDF low-pressure dual-fuel (LPDF) two-stroke engine used for propulsion. The ship was built in 2021, and the measurement campaign was the ship’s second voyage. LPDF two-stroke gas engines are currently the most popular for new ship builds, and to date, there has been no published direct measurements of uncombusted methane in engine exhausts (methane slip) while in operation, which is consequently the key to estimating fleet emissions in the future. The ship houses two dual-fuel main engines for propulsion and four dual-fuel generator engines to produce power for other ship demands.

The researchers boarded the ship on March 25, 2021, while it was anchored off the port of Corpus Christi, US. The ship docked and loaded the cargo in Corpus Christi on March 27 and began the laden voyage across the Atlantic on March 28. The laden voyage lasted 16 days until the ship docked in Zeebrugge, Belgium on April 13 to discharge the cargo. The returning ballast voyage to the US began on April 14, with the ship refueling in Portland, UK, before it reached Corpus Christi on April 28.

The emissions were dominated by CO2, both from the main engines (45% of total GHGs) and the generator engines (18%). Methane emissions contributed 35% of the total GHG using global warming potential (GWP) over 100 years. However, using GWP over 20 years, this dominance is switched, and methane contributes 56% of the total GHG.

The study suggested that these engine methane slip emissions can be reduced as much as by half by operating the engines at higher loads. It noted that this was the Galveston’s second voyage, that multiple engines were used at lower loads for operational reasons and that carriers often utilise engines at higher loads.

It recommended the installation of methane emissions monitors on engine exhausts to monitor and report more accurate methane emissions estimates and to support methane mitigation operational practices.

Dr Paul Balcombe, the principal investigator and lecturer in Chemical Engineering and Renewable Energy from Queen Mary University of London said: “This study helps to fill a big data gap when it comes to methane emissions from LNG shipping. It’s vital that we understand what their emissions profile is at a time when LNG imports are likely to grow substantially to reduce Europe’s reliance on Russian gas.

“This study is the first-of-a-kind to measure total methane emissions from engines aboard LNG carriers, including venting and fugitive emissions, but we need to do much more to get a representative sample of the approximately 600-strong LNG fleet. As well as these academic measurement studies, increased monitoring of emissions from engines, vents and fugitives would allow us to identify and implement effective reduction measures as hotspots are found.”

LNG carrier (LNGC) was chosen for measurement due to the WinGD XDF low-pressure dual-fuel (LPDF) two-stroke engine used for propulsion. The ship was built in 2021, and the measurement campaign was the ship’s second voyage. LPDF two-stroke gas engines are currently the most popular for new ship builds, and to date, there has been no published direct measurements of uncombusted methane in engine exhausts (methane slip) while in operation, which is consequently the key to estimating fleet emissions in the future. The ship houses two dual-fuel main engines for propulsion and four dual-fuel generator engines to produce power for other ship demands.

LNG carrier (LNGC) was chosen for measurement due to the WinGD XDF low-pressure dual-fuel (LPDF) two-stroke engine used for propulsion. The ship was built in 2021, and the measurement campaign was the ship’s second voyage. LPDF two-stroke gas engines are currently the most popular for new ship builds, and to date, there has been no published direct measurements of uncombusted methane in engine exhausts (methane slip) while in operation, which is consequently the key to estimating fleet emissions in the future. The ship houses two dual-fuel main engines for propulsion and four dual-fuel generator engines to produce power for other ship demands.

Good start but the sample size of 1 ship is too soon to speak. I’ve sailed recently on a similar newbuilt ship and the generators were running underloaded almost constantly. Reasons spanned from poor power balance during speed trials and normal operation, people trying to “protect” the engines by keeping them between 50 and 70% load and the “green” argument that operating on gas the engine will not develop too much deposits compared to HFO low load operation.

It’s just to soon to tell but i have a feeling that generators on X-DF ships will be extremely fuel efficient and kind to the environment.

The main problem is due to the price and disparity of gas, owners are doing everything to burn as less as possible, no more than the BOR. If the BOR is low enough generators are kept on gas and X-DF main engines run on HFO with fuel sharing (liquid fuel / gas fuel) to keep cargo tank pressure.

Very useful information.

One is tempted to ask, “How many of these dual fuel gas carriers have a shaft alternator fitted? If not, why not?”

Some do but not as often. One reason can be the need for lots of power availability alongside (running high capacity ballast pumps and ballast water treatment system, cargo equipment: cargo pumps, LD / HD compressors), when the main engine is stopped.

Ships with 2 stroke propulsion engines usually have 3 or 4 diesel generators which can burn HFO / MGO or GAS. Ships with steam turbine propulsion can have 2 turbo generators and most of the time have also 1 small diesel generator, which is used for maximum 1 hour per month at best (testing purpose).

For instance on my last ship ( membrane type, 2 x X-DF 2 stroke engines and 4 diesel generators) we were running constantly 2 DG’s on gas, 2 on stand-by and both propulsion engines were usually kept on ultra-low Sulphur fuel oil. One clear reason was cost-effectiveness as HFO was way cheaper than natural gas. Truth be told the ship was basically new and fitted with elaborate systems to keep the Boil-off rate to extremely low values.