Circular Maritime Technologies International (CMT) from the Netherlands has debuted a brand new way of breaking up ships, where humans are not placed in danger.

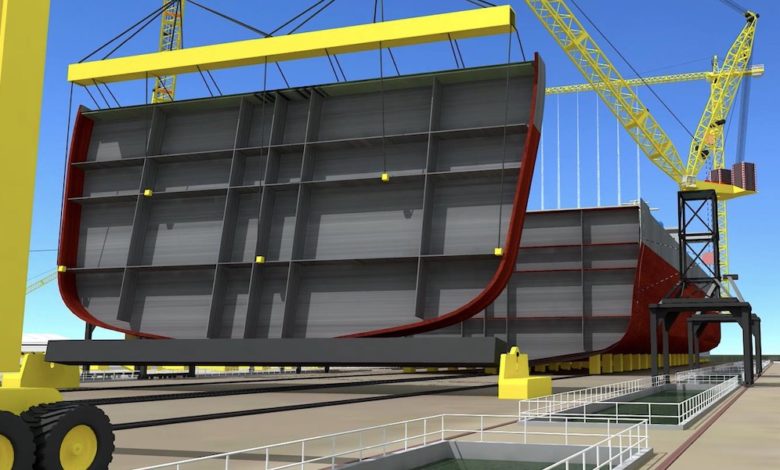

At CMT’s proposed yard, no human lives will be put at risk as the ships will be taken out of the water and dismantled by a fully mechanised and automated system (pictured).

A proof-of-concept prototype is planned to be launched in the Netherlands soon with the company claiming it will then establish yards with international partners and attract business from shipowners by matching the price paid by South Asian competitors.

The proposed CMT yard runs on its own power and produces clean steel. The yard will reduce the size of the vessel step by step through various automated tools, up to the point where each part of the ship’s steel structure is reduced to many small pieces. The CMT yard will go from a 3D structure to a 2D material package of steel plates, a process the company says will be executed quickly and precisely, managed by tailored control tools and software, overseen by specialised CMT staff.

Among CMT’s backers are Damen Shipyards, Huisman Equipment, Jansen Recycling Group, and Sojitz Corporation.

Many in shipping have been demanding more advanced and greener recycling options in an industry that has had to contend with the exit of China, deemed the most environmentally conscious of the shipbreakers, four years ago.

Signing up for the SteelZero initiative earlier this year, Danish carrier Maersk said that more than 700 of its operated vessels are projected to be recycled in the next decade.

Speaking on the occasion, Palle Laursen, senior vice president and chief technical officer at Maersk, noted: “Global ship recycling volumes are projected to nearly double by 2028 and quadruple by 2033. Recycled steel will progressively be recognised as a viable raw material for steel consumers with net-zero emissions targets.”

Driving circularity in the steel industry, Laursen said, would help Maersk reduce its Scope 3 emissions.

Impending legislation from the International Maritime Organization such as EEXI and CII is widely anticipated to make a tranche of the global fleet obsolete.

Dear Sam

Great article and great news.

As the president for many years of Astakos Shipbreaking Company SA in Greece designed the green semi automatic ship recycling. I am also a naval architect that has built many many ships.

Knowing all too well the processes both of building and of recycling I am of the opinion the designers of the fully automated unmanned ship recycling method must be looking at different ships to which I am accustomed building and recycling.

We have automated shipbuilding but at a point humans are there to complete it.

To dismantle we must follow the reverse.

Once the steel is cut by automation means to large pieces by many diverse robotic cutting machines driven by controllers sitting behind large console where the twin ship will be portrayed, there are machines that are called hydraulic shears that bundle and cut in prescribed sizes that are ready to be used by the steel mills.

At my closing I congratulate the company for trying.