North America responsible for the world’s container shortages

New analysis from Danish consultancy Sea-Intelligence shows just how much North America is to blame for the severe equipment imbalances challenging the global container shipping industry.

The continent’s comparatively slow handling of containers has long been a source of supply chain pain and a leading cause of empty container shortages in Asia, but never to the extent recorded today.

Before the pandemic North America was structurally responsible for 40-45% of the empty imbalance needed in Asia, according to analysis from Sea-Intelligence. Following the early pandemic volatility this changed sharply, so that North America is now structurally responsible for 55-60% of the imbalance in Asia.

Sea-Intellligence warned in its latest weekly report that the structural supply chain imbalances related to empty containers are not approaching normalisation.

“The imbalance problem now needs to be rectified through North America – which at the same time is the place with the worst port congestion problems, which slows down efforts to repatriate containers,” the report from Sea-Intelligence stated.

The issue was widely discussed at this year’s virtual TPM conference – the world’s largest container shipping gathering.

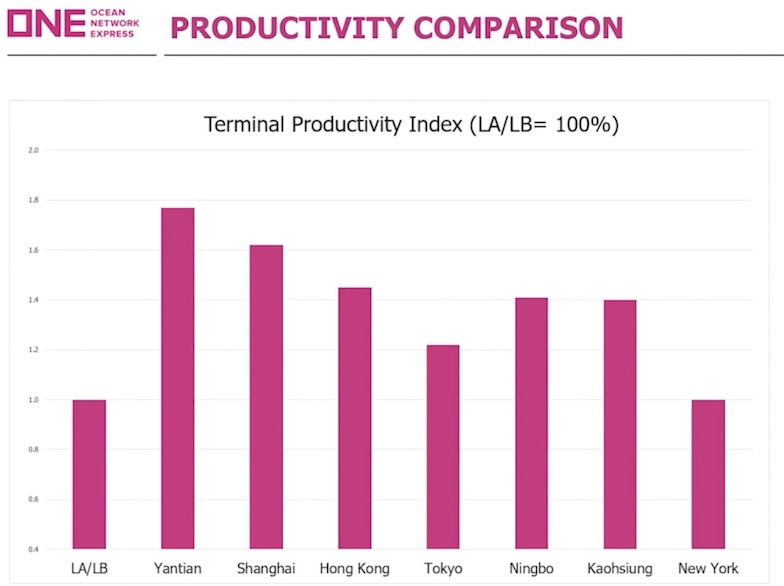

Speaking at the event, Jeremy Nixon, the CEO of Japanese liner Ocean Network Express (ONE), pointed out that terminal productivity in North America lags Asian counterparts by up to 50% thanks to less working hours.

Speaking at the same event, Vincent Clerc, the CEO of A.P. Moller-Maersk Ocean & Logistics, the world’s largest containerline, said the underinvestment along the coastline of North America was a critical part of today’s backed-up box crisis.

US regulator, the Federal Maritime Commission, is looking into the issue of equipment availability as part of a wide ranging investigation into the supply chain chaos that has hit the nation’s ports, retailers and exporters over the past eight months.

Latest data from PIERS, which tracks US imports and exports, shows container volumes from Asia to the US grew 90% in March compared to March 2020. Even when comparing March 2021’s figure to the pre-pandemic March 2019, the volume growth is up by a record 57%.

New analysis? Latest weekly report?

The ONE chart and findings were already published a couple of months ago and the North American imbalance has been existing for as long as containers have been in existence.

Yes, the bottle-necks have been exacerbated by an increasing inward (eastbound Transpac) flow from China etc., caused by the Stop-Go nature of the pandemic consumer pattern but the imbalance has always been there. Nothing new under the sun.

These people should get a life. Americans are working just as hard and long as anyone else.

Do you really think the Chinese government puts the same restrictions on their workers that the United States does especially the longshoreman’s unions?

They are not. The article states that Americans are working less than the Chinese counterparts. Granted, there are no data points provided to prove it but it is not hard to believe that the Chinese are being forced to work several hours more than what would be considered a “normal” work day in western culture

No, we’re not. Nor should we. The pattern of worker abuses prevalent in asian and ME nations is not something we should take our examples from

Then get more people to do the work. Your inability to process these containers is causing us to lose business because shipping costs have increased 10 fold due to no containers being available. GET YOUR ACT TOGETHER USA!!!!!

blockchain makes carriers’ neurons lazy. Just like GPS with deck cadets.

How lazy of you to not send in your comment on a slate rock.

Oh yes the deck cadets should spend hours over an old wooden chart table mapping out their next route instead of using a highly accurate digital map system that has constantly updated dangers, buoy locations, lighthouse signals and changes to the coast line. If you can’t understand that a GPS navigation system makes a voyage safer and a more reliably fast trip, and allows the cadets and bridge crew to focus on things like weather conditions, course corrections, obstacles, and other safety measures like checking and maintaining cargo, or basic ship maintenance like painting and chipping rust, sewing tarps, scrubbing chains and cleaning the ship overall, then you are the one that needs to exercise those neurons. I worked as a bridge watchman and there’s plenty to keep you and your neurons focused in the over 15hrs of work you have to do each day. Don’t talk about shit you don’t know a lick about, mate.

The container imbalance lately has been exactebated by ILWU trying to renegotiate their union contracts with the covid 19 exposures and 4 deaths of fellow Longshoremen passings. We will all see how it will play out this summer after some of the inbound containers are released back to China and Asia for more shipments to return.

Somebody seriously needs to buy the UPRR and get those trains seriously moving.

You’re way off Donald. It was 12 people that passed from COVID in a 55 day span on the waterfront and negotiations are not for another 14 months…

It’s a lack of equipment and overall preparedness for this amount of volume. Not to mention automated terminals failing to produce the numbers you see at a conventional operation. EVERY cog in the supply chain was impacted.

Automation is another huge problem, it is failing. 68 moves in a shift will not cut it. It doesn’t work at a throughput port like LA & LB. always shut down or just moving too slow.

Total BS article from someone who is obviously a huge fan of China. China is responsible for the world’s shipping container shortage, and the more intelligent people of the world agree with that fact.

It’s not about being a fan or politics. It is just a fact.

There are serious turnover issues. Which means more volume but less people to handle it. In the end, The total man hours are much less than our counterparts elsewhere.

Yeah all those rural Chinese people who don’t even have Internet are the ones ordering stuff on Amazon.

What’s your beef, Tom? The problem is delays at the ports? In Los Angeles?. Blame the Donald? Or scape goat Asia? Aye! Classic Trump style?

Innovation failure, too comfortable the life in America ?

Presumption stop blame the OTHER side,, the Asians,, (Trump style aye,,) not going to help we the people of the world?

Stop grumbling ,,,, prices going up in America with all that backlog at the ports?

It’s EXTREMELY amusing how you fail to mention the chassis shortage? The rail cart shortage? The DRIVER shortage? The port workers shortage? And let’s not forget the immense COVID outbreak that just occurred in February- March 2021 at the LAX and LGB ports which lowered those ports to only have 60% of their working employee bodies. Every single day is a 12 HOUR DAY MINIMUM AT THE LEAST FOR ALL OF US. We have family and children. Get your facts straight before you go running to point the finger.

Tanks

And you’re crying all of the way to the bank…

China is God and they are very nice too. 5000 deaths from Covid and we can trust them. Woke media being woke.

Can you name those people your sources im curious to know where you get your info as i see in person daily the opposite. What ports have you been too to back your statement?

The CCP has purposely pulled 70% of thier Global Shipping fleet out of the lanes and has idled 70% of the CIMC intermodal factories in Yuangzhou and other areas..

This is in response to a rapid GDP drop in China and the amount of goods inward to the USA due to higher Tariffs..

The port congestion is just another side effect that has been in the mix for many years.. When you start draining the water now you see some of the rocks on the river

What a load of steaming bull shit. How one sided can you be. The slant on this article is so obvious.

Ships get larger and able to carry more containers at one time. This causes equipment availability to be in sink with the ships arrival and departure. If the ships are not on schedule It dramatically impacts equipment availability. Stand by time, late pick up or delivery, etc. Slow and steady is better than, Here comes five thousand containers at one time scramble.

China stopped “recycling” (dumping trash in pits in China for money) for the US and that essentially ended the largest source of return shipping containers. It is very expensive to transport empty containers so they pile up in the US.

True story

We never had this problem back in the day when we produced all of our needs and were only flooded by Japanese crap, however their crap turned into pretty good stuff over the years compared to chinese junk of today. Everything is made not to last! We need to get back to business here!

They took our jobs! Took our jobs! Te tu tur tur!

This only proves the Americans are the greatest consumers in the world, of course the flow of containers INTO USA, is by far higher than the flow GOING OUT FROM USA.

All of the other presumptions will never be as significant as this fact.

I am going to say it, “fake news”. The problem is LA/LB is getting slammed with vessels full to the brim, all the while we return vessels at half capacity.

The LA/LB port has plenty of empty containers ready to load out, but apparently there is ZERO PROFITS, in returning empty containers back to China. Bc of this FACT, LA/LB are returning vessels back with, wow, the exact percentage of this discrepancy.

The companies are NOT WILLING to have a vessel sit any extra hours to load empties.

That’s the FACT, Jack.

this is what happens when you foist a false narrative on the global market.